I posted this yesterday and posted them via my phone while I as freeing the parts from the support structure. Now I’m going through the pictures to reinsert them into wordpress so their not so big and add some descriptions. Clicking on them will still produce full resolution. These parts were printed at the 3dprintingstore (Denver, Co) on a B9 Creator.

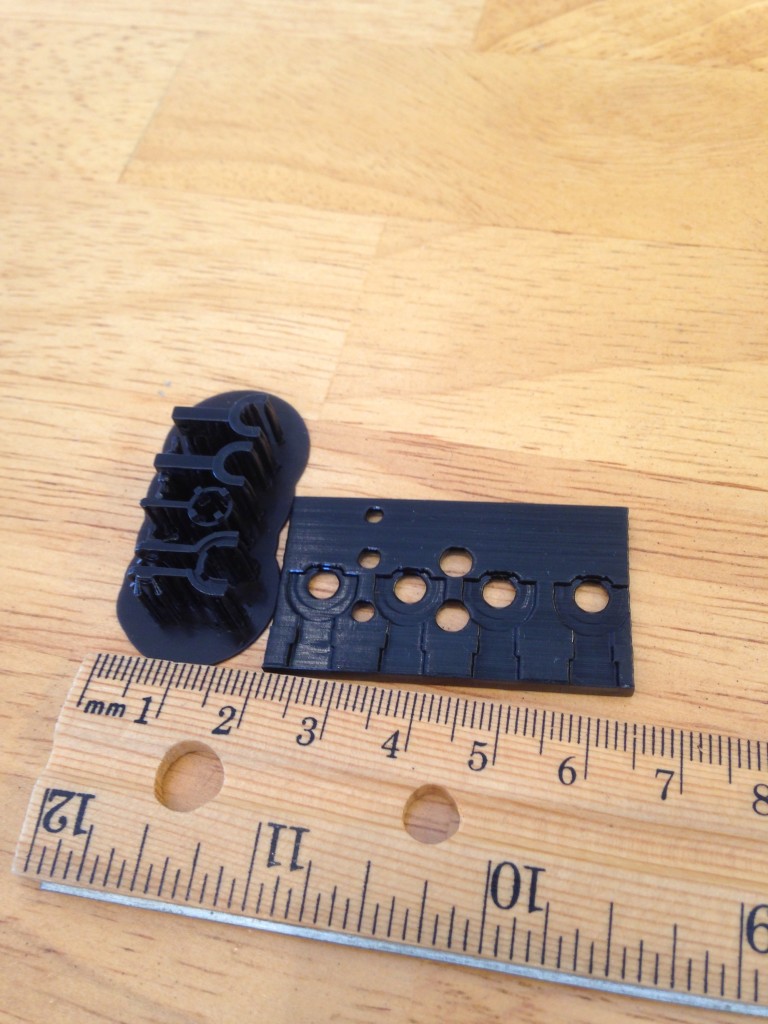

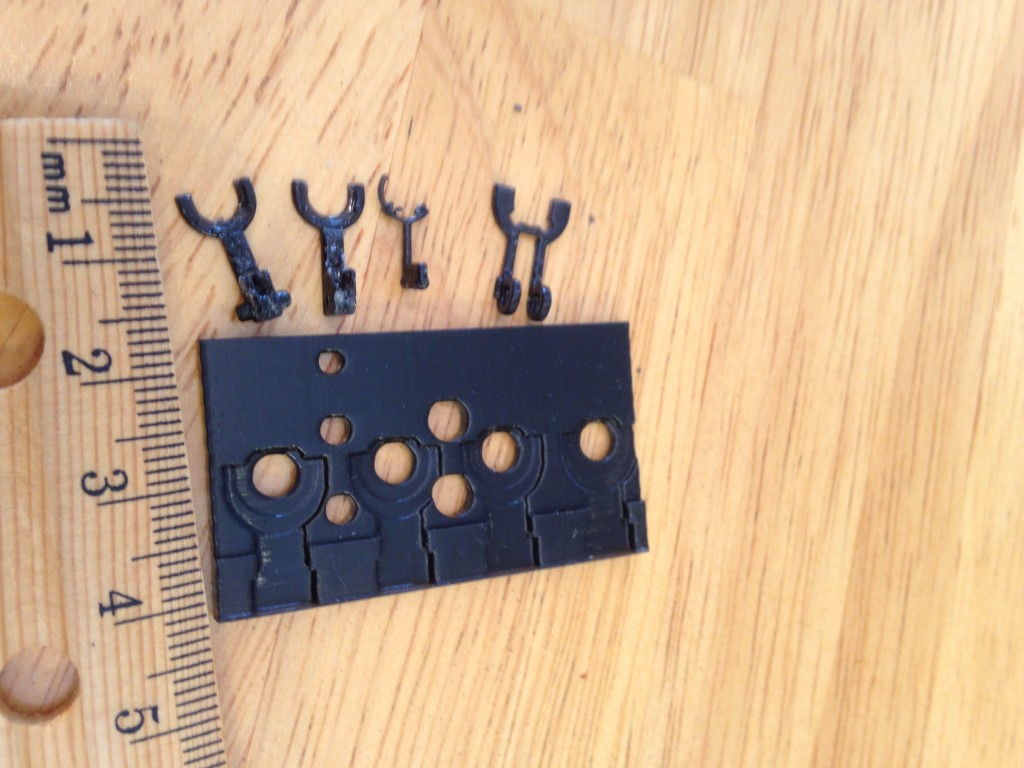

I used small clippers to cut them free. Perhaps I needed to be a little more careful as I ended up cracking the o-ring remover. Here here is pictures of the parts cut free.

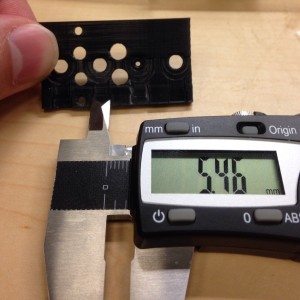

The hinge between the spatula and clamper worked as in it swings around the hinge! (1st time). Here is a pic of that and the dimensions that worked.

Here’s a drawing of how it looked in cad. I had to make the tolerance between the parts 300 um to get it to be able to move.

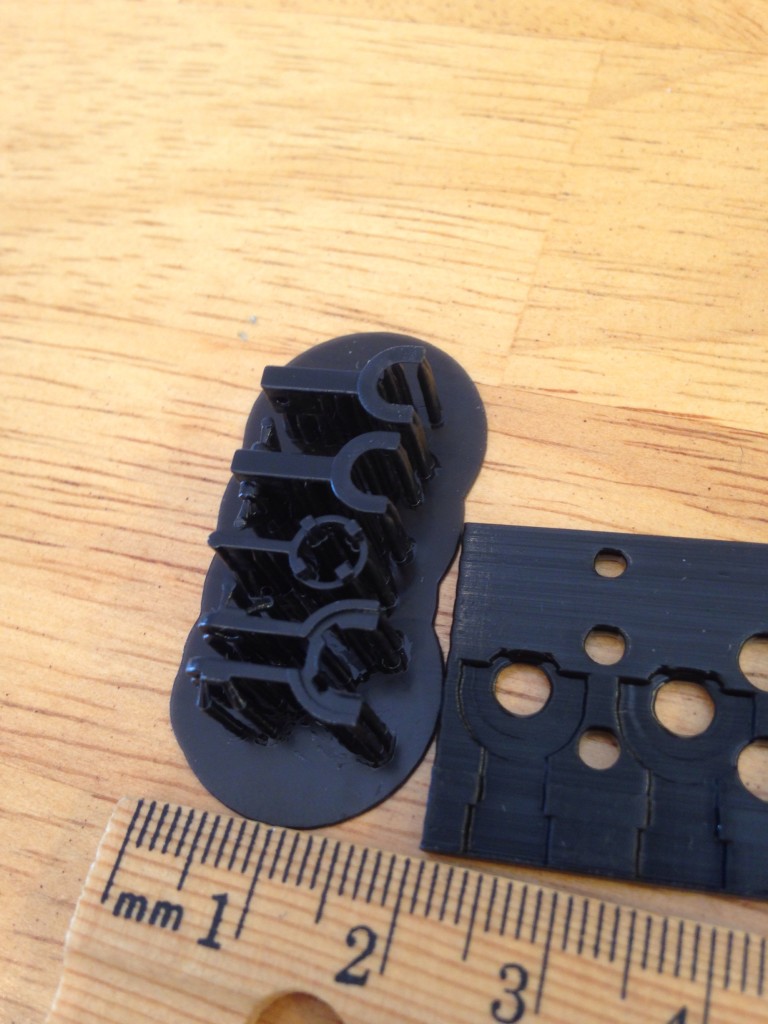

The dove tail redesign worked as well. Here is a look at pics of it sliding into the filter spatula.

Here is the drawing of that feature with tolerances. They were expanded since previous print

I still have 2 features that didn’t work that are the notch on the plate and the teeth of the o-ring remover. The plate also came back slightly undersized.